Search This Supplers Products:welding machineAc/Dc Tig WelderPulse Mig WelderPlasma CutterMig Welding MachineTig Welding Machine

What is plasma?

time2017/08/11

- The combination of cut quality, productivity, operating cost, and versatility make plasma today’s most popular industrial cutting process.

What is plasma?

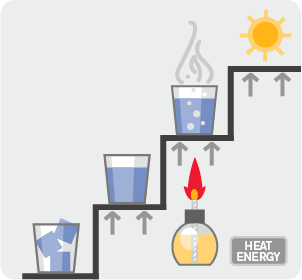

Plasma is the fourth state of matter. We normally think of three states of matter: solid, liquid and gas. For a common element, water, these three states are ice, water and steam.

The difference between these states is their relative energy levels. When you add energy in the form of heat to ice, the ice melts and forms water; if you add more energy, the water vaporizes and becomes steam. If you were to add considerably more energy to the steam – heating it to about 11,700° C – the steam would break up into a number of component gases, and would become electrically conductive, or ionized. This high energy ionized gas is called plasma.

A plasma cutting system uses a plasma stream to transfer energy to a conductive work material. The plasma stream is typically formed by forcing a gas such as nitrogen, oxygen, argon — or even air — through a narrow nozzle. An electric current produced by an external power supply adds sufficient energy to the gas flow to ionize it, turning it into a plasma arc with temperatures approaching 40,000˚ F. The plasma arc cuts the workpiece by melting it, and blows away the molten metal.

Plasma system components

A basic plasma cutting system includes the following components:

- - A constant current DC power source. The open circuit voltage is typically in the range of 240 to 400 VDC. The output current (amperage) and overall kilowatt rating of the power supply determines the speed and cut thickness capability of the system. The main function of the power supply is to provide the correct energy to maintain the plasma arc after ionization.

- Arc starting circuit – In most liquid-cooled torches of 130 amps and higher, this is a high frequency generator circuit that produces an AC voltage of 5,000 to 10,000 volts at approximately 2 MHz. This voltage creates a high intensity arc inside the torch to ionize the gas, producing the plasma. Rather than the high frequency starting circuit above, air plasma torches typically use a moving electrode, or “blowback start” technology to ionize the gas.

- Torch - This serves as the holder for the consumable nozzle and electrode, and provides cooling (either gas or water) to these parts. The nozzle and electrode constrict and maintain the plasma jet.

Typical applications and industries

Plasma is used in both handheld and mechanized systems to cut a wide range of conductive materials, including mild steel, carbon steel, stainless steel, aluminum, copper, brass, and other metals.

Cutting applications include:

- Straight cutting

- Bevel cutting

- Gouging

- Hole cutting

- Extended reach cutting and gouging

- Fine feature cutting

- Marking

Industries and markets include:

- Farming and ranching

- Shipbuilding

- Mining

- Energy

- HVAC and mechanical fabrication

- Steel service centersg

- Construction equipmentg

- Automotive restoration

- Artwork, signs, and ornamentation

- Pipes and pipelines

- General construction

- Civil service construction

- General fabrication and job shops