Search This Supplers Products:welding machineAc/Dc Tig WelderPulse Mig WelderPlasma CutterMig Welding MachineTig Welding Machine

-

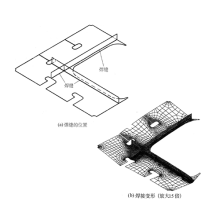

What can we do to prevent the parts being distorted after welding?

time2016/07/15

-

MIG welding tip...Get a better Ground clamp. This is probably one of the most important mig welding tips ever!

time2016/07/19

-

Keep wire in a clean, dry place when not welding, Rusty wire will not help us now... will it?.

time2016/07/21

-

Use gas lens style collet bodies and cups to weld stainless steel. The screen in the gas lens allows far better gas coverage of your welds.

time2016/07/21

-

Tungsten size should be selected mainly according to amperage AND polarity and not always dependent upon metal thickness.

time2016/07/22

-

On transformer tig welders, forgetting to set high frequency to continuous when tig welding aluminum …..

time2016/07/25

-

" sideways scratches on your tungsten will also cause pandemonium and the end of the world as we know it."

time2016/07/26

-

Because helium carries so much more energy and heat than argon, aluminum can be puddled very quickly so a puddle can be made very quickly even on very thick aluminum.

time2016/07/27

-

Usually AC is better for these situations. also, if you have large gaps to fill AC is usually better.

time2016/07/28

-

Well there is always a bit of fudge factor because flowmeters are different, and machines are different …

time2016/07/29

-

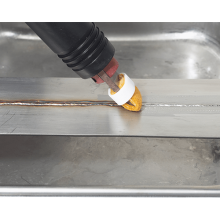

If you are welding stainless pipe with a purge and your weld is still sugaring, remember argon is heavier than air and flows like water.

time2016/08/01

-

The more vertical the torch is, the more arc is directed into the part. Think about it like this…

time2016/08/02

-

Put a vent hole in anything you weld that will be sealed up completely or air will heat up and expand and blow away your shielding gas or even blow out at the end of the weld bead.

time2016/08/03

-

Set the machine so that you are at welding amperage with the foot pedal depressed about 3/4 of the way.

time2016/08/04

-

Extend the tungsten out of cup 1/4” to 5/16” when welding high amperage aluminum or heat will radiate from the cup to tungsten and reduce output, especially if the orifice is too small.

time2016/08/05

-

Don’t use too much torch gas when welding aluminum on AC. Aluminum takes a lot of amperage to weld.

time2016/08/08

-

Ideally, torch angle should only be around 10 degrees or less. Too much torch angle will deflect the heat and melt the rod before you ever get it into the puddle.

time2016/08/09

-

Shielding gasses for TIG welding Argon is not the only shielding gas used for TIG welding…

time2016/08/10

-

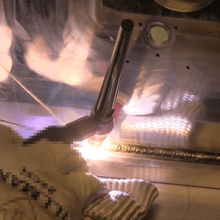

TIG welding is not nearly as forgiving as Mig or stick when it comes to dirty metal. For TIG welding, the metal needs to be clean; no rust, scale, paint, etc.

time2016/08/11

-

If you have problems feeling the wire with a glove, Try some mechanics gloves or really soft and thin tig gloves like Topwell BL-1005 skin tig gloves or even some woven cotton gloves...

time2016/08/12

-

Use stainless steel wires for stainless steel, aluminum wires for aluminum, and steel wires for steel and nickel alloy rods for nickel alloys. (cast iron is welded with nickel wire but that’s a story for another day)

time2016/08/16

-

TIG welding filler wire and Mig welding wire from a spool are essentially the same composition except that mig welding wire often contains more silicon and that can actually be a good thing for TIG welding steel.

time2016/08/17

-

-

-

-

-

-

-

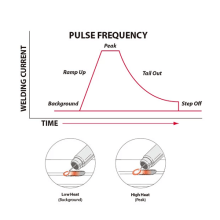

The Pulsed TIG function switches the amperage from a high(peak) to a low(background) at a set rate(PPS). Pulsing can reduce heat input by lowering the average amperage, increasing control of the weld puddle, penetration and distortion. The following parameters can be adjusted for desired results:

time2016/09/07

Publishersandy

-

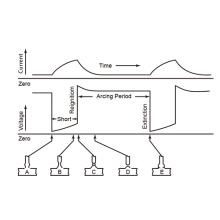

The gas metal arc welding (GMAW) process uses four basic modes to transfer metal from the electrode to the workpiece. Each mode of transfer depends on the welding process, the welding power supply, and the consumable, and each has its own distinct characteristics and applications.

time2016/09/26

Publishersandy

-

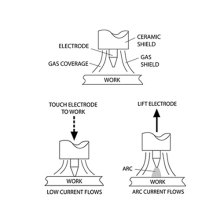

If you are left “scratching” your head about the differences in the different start methods of TIG, you are not alone. Many experienced users get the facts wrong when it comes to the 3 basic ways you can start a TIG arc.

time2016/09/29

Publishersandy

-

AC Frequency control

AC Balance Control

Amplitude Controltime2016/10/11

Publishersandy

-

-

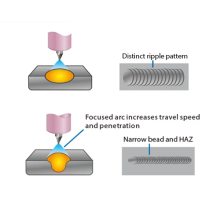

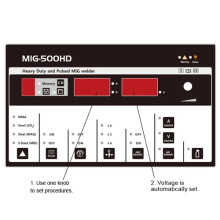

In simple terms, pulsed MIG is a non-contact transfer method between the electrode and the weld puddle. This means that at no time does the electrode ever touch the puddle.

time2016/10/27

PublisherPiya

-

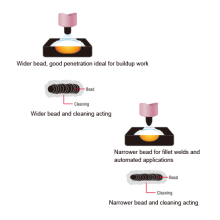

As we all know that, MIG torch plays a very important roles in MIG welding, it can do wire feeding, gas feeding, and power switch. There are three method of wire feeding:Push, spool and push-pull.

time2016/11/04

Publisherpiya

-

-

Stick Welding (SMAW or Shielded Metal Arc Welding)

MIG Welding (Metal Inert Gas, also known as GMAW or Gas Metal Arc Welding)

Flux Cored Arc Welding (FCAW)

TIG Welding (Tungsten Inert Gas, also known as GTAW or Gas Tungsten Arc welding)time2017/04/05

-

The combination of cut quality, productivity, operating cost, and versatility make plasma today’s most popular industrial cutting process.

time2017/08/11

-

-

Always read and follow the safety precautions and operational instructions in your owner's manual.

time2017/08/31