Search This Supplers Products:welding machineAc/Dc Tig WelderPulse Mig WelderPlasma CutterMig Welding MachineTig Welding Machine

Why should I try TIG Welding?

time2017/10/17

- TIG welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze, and even gold. TIG is a useful welding process for welding wagons, bike frames, lawn mowers, door handles, fenders, and more.

Why should I try TIG Welding?

1. Weld more metals and alloys than any other process

TIG welders can be used to weld steel, stainless steel, chromoly, aluminum, nickel alloys, magnesium, copper, brass, bronze, and even gold. TIG is a useful welding process for welding wagons, bike frames, lawn mowers, door handles, fenders, and more.

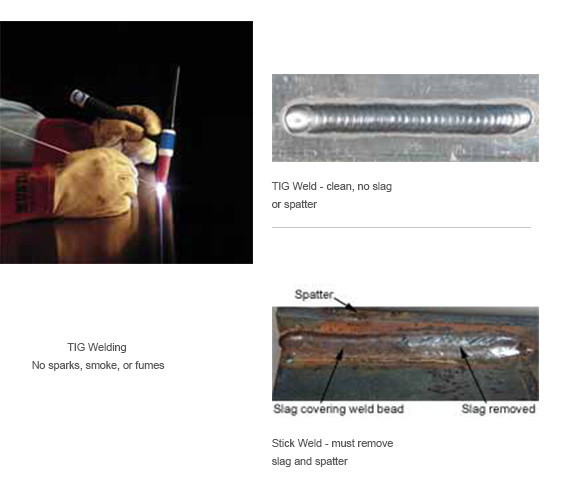

2. Create high quality, clean welds

With superior arc and weld puddle control, TIG allows you to create clean welds when appearances count. Because the heat input is often controlled by pressing on a foot pedal, similar to driving a car, TIG welding allows you to heat up or cool down the weld puddle giving you precise weld bead control. This makes TIG welding ideal for cosmetic welds like sculptures and automotive welds.

No sparks or spatter

Because only the necessary amount of filler metal is added to the welding puddle, no spatter or sparks are produced (if the metal being welded is clean).

No flux or slag

Because the Argon gas protects the weld puddle from contamination, no flux is required or used in TIG welding and there is no slag to block your view of the weld puddle. Also, the finished weld will not have slag to remove between weld passes.

No smoke or fumes

TIG welding does not create smoke or fumes, unless the base metal being welded contains contaminants or elements such as, oil, grease, paint, lead or zinc. The base metal should be cleaned before welding.

3. Use one shielding gas (Argon) for all applications

Because Argon can be used to TIG weld all metals and thicknesses you only need one type of gas in your shop to handle all of your welding projects.

Argon gas is typically used for most TIG welding applications

Argon gas is typically used for most TIG welding applications4. Weld in all positions

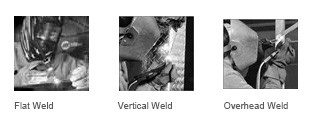

TIG welds can be made in all positions - flat, horizontal, vertical or overhead. Perfect for roll cages and inside confined areas.