Search This Supplers Products:welding machineAc/Dc Tig WelderPulse Mig WelderPlasma CutterMig Welding MachineTig Welding Machine

-

These welding tips are meant to be helpful hints. See your equipment Owner’s Manual for all safety and operational information.

time2019/10/09

-

These welding tips are meant to be helpful hints. See your equipment Owner’s Manual for all safety and operational information.

time2019/10/12

-

These welding tips are meant to be helpful hints. See your equipment Owner’s Manual for all safety and operational information.

time2019/10/15

-

These welding tips are meant to be helpful hints. See your equipment Owner’s Manual for all safety and operational information.

time2019/10/18

-

The Updates of the

welder PROMIG-500SYN DPulse XT for Mild Steels. High efficiency, complete penetration ... time2019/10/23

-

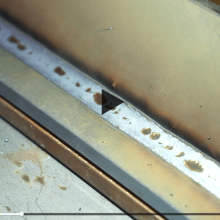

Full Penetration Square Butt Weld

Thickness: 6mm

Gap: 1mm

Speed: 400mm/min

No spatters, HSP Pulse MIG process(M.S)time2019/10/31

Formyoutube

-

#Happy Halloween# Trick or Treat, Give you sweet. Ask TOPWELL for surprises!!

time2019/11/01

-

The following 7 tips will not only improve your overall technique, but they will help to keep you safe on the job.

time2019/11/07

-

AC versus DC is a long held debate. Is it better for a current flow to be unidirectional or alternating from positive to negative? In the end, DC is best for MIG welding and AC is best for TIG welding. AC is also suitable for stick welding. You will have to take some precautions. In any case, electricity is like fire and money; a wonderful servant but a terrible master. Use it wisely and you can be proud of a job well done.

time2019/11/15

-

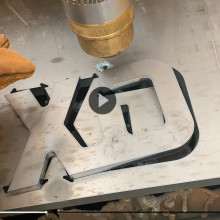

#HSP MIG# Process: the perfect welding for 6mm Mild Steel by Topwell PROMIG 500SYN DPulse - High deposition.

time2019/11/18

-

-

Your use of MIG or TIG welding could be the difference in your project that takes it to the next level. You could greatly reduce the time and effort spent making it and improve the quality and durability of the final product.

time2019/12/04

-

Your use of MIG or TIG welding could be the difference in your project that takes it to the next level. You could greatly reduce the time and effort spent making it and improve the quality and durability of the final product.

time2019/12/06

-

Arc welding processes are as varied as the work pieces they create, and choosing the right one is vital to your project’s success. While MIG and TIG welding both form the weld using an electric arc, the techniques are quite different, and choosing the wrong one can lead to more than one headache. Read on for the reasons you may want to choose MIG welding vs. TIG welding.

time2019/12/11

-

TIG Welders fall into three categories: light, industrial, and heavy duty

time2019/12/13

FormThis entry was posted on March 28, 2015 by admin

-

-

-

Of all the arc welding processes, TIG (tungsten inert gas) welding is capable of achieving the highest quality welds and is the most versatile in terms of what can be welded and the position of the welds. As in most industrial processes, however, quality comes at the expense of time and TIG is generally slower than MIG or MMA welding. But, where weld integrity is critical, production engineers are prepared to accept the additional process time.

time2019/12/27

-

In many cases, MIG gun consumables may be an afterthought in the welding process, as concerns with equipment, workflow, part design and more dominate the attention of welding operators, supervisors and others involved in the operation. Yet, these components — particularly contact tips — can have a significant impact on welding performance.

time2019/12/27

-

Benefits of low-frequency pulse MIG welding

time2020/01/03

-

Pulsed MIG/MAG welding is a variant of the conventional MIG/MAG welding process in which the current is pulsed. Pulsing was introduced originally for control of metal transfer at low mean current levels by imposing short duration high current pulses. The cycle consists of applying the repeated pulse current over a constant background current:

time2020/01/03

-

Always read and follow the safety precautions and operational instructions in your owner's manual.

time2020/01/10

-

-

Aluminum and Stainless Steel might look similar, but they are actually quite different. Keep these 10 differences in mind when deciding which type of metal to use in your next project:

time2020/01/14

-

Warped metal, charcoal-colored welds, and frustration; these are some of the things that can happen when welding stainless steel.

time2020/01/14

-

The joining process of two metal elements through melting is known as welding. It is not an easy job. It is pretty much challenging.

time2020/06/30

Form网络

-

The joining process of two metal elements through melting is known as welding. It is not an easy job. It is pretty much challenging.

time2020/06/30

-

-

-

With the ever-changing situation with COVID-19, we have worked out a series of business continuious plan, making sure that only minimal delays will occur.

Our business continuity plan takes many factors into consideration.time2020/06/19

-

TOPWELL ProMIG-250SYN DPulse

Double Pulse MIG process

1.2mm 5356 aluminum wire

2mm aluminum plate

Job number: 803

Welding amperage: 78Atime2020/09/07

-

Pulse MIG(spray-arc transfer) for welding aluminum by Portable MIG, ProMIG-200SYN Pulse

time2020/09/01

-

TOPWELL PRO300 With HPRXD Cutting Demostration

time2020/09/10

-

Extra-definition plasma cutting system TOPWELL PRO300

M.S 20mm cutting test

Speed 2000mm/min

Gas Oxygen&Air

Automatic Gas Consoletime2020/08/03

-

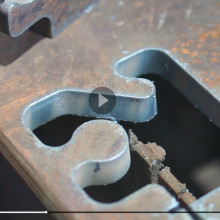

Metal: ASTM1045/ S45C/ C45 carbon steel

Thickness: 23mm

Machine: TOPWELL PROCUT-75MAXtime2020/10/12

-

Gas: Air only, by Water-spray shields

Thickness: 16mm

Speed: 230A/165V @ 1000mm/min

Cut angle: less than 1 degree (Range 2, ISO 9013)

Torch: TP-200

Visit our website for more detailstime2020/09/30

-

Synergy Pulse MIG process

1.0mm 4043 aluminum wire

2mm aluminum plate

Job number: 604

Welding current: 76Atime2020/10/16

-

Synergy MIG process

0.8mm mild steel wire

2mm mild steel plate

Job number: 202

Welding current: 133Atime2020/10/21

Formyoutube

-

Synergy Double Pulse MIG process

1.0mm 5356 Aluminum wire

2mm aluminum plate

Job number: 802

Welding current: 78A

By TOPWELL ProMIG-250SYN DPulse

Visit our website for more details:

http://cn-topwell.com/ProMIG-250SYN%20DPulse-Overview.html

Contact us by email: sales@topwellwelders.comtime2020/11/16

FormYoutube

-

Synergy Pulse MIG process

1.0mm 5356 Aluminum wire

2mm aluminum plate

Job number: 802

Welding current: 75A

By TOPWELL ProMIG-250SYN DPulse

Visit our website for more details:

http://cn-topwell.com/ProMIG-250SYN%20DPulse-Overview.html

Contact us by email: sales@topwellwelders.comtime2020/11/11