Rated Input Voltage 1PH ~ 230V ±15%

MAX.Load Power Capacity 10.35KVA

Rated Output 250A/26.5V

Max Open Circuit Voltage 55V

Effiency 80%

Wire-feed Mechanism 4 Rollers

Wire Feed Speed Range 0~25m/min

Warranty 1 year warranty

Dimension 770X250X650mm

Weight 32KG

- 85cm x33cm x67cm

-

Min Order1 piece

ALUMIG-250P is a synergic ,pulsed and double pulsed MIG/MAG welding machine,For these regular welding jobs

/FEATURES

Quick Specs

- Application:

- Metal Fabrication

- Maintenance and Repair

- Auto Body

- Light Industrial

- Processes:

- MIG,

- Flux-Cored,

- Pulse MIG,

- Double Pulse MIG,

- MMA(Stick)

- Input Power:250P: 230V, 1-Phase

- 300P: 400V, 3-Phase

- Amperage Range:250P: 10-250A/300P: 10-300A

- Rated Output at 40℃ (104℉):

- 250P: 250A at 26.5V @60% Duty Cycle

- 300P:300A at 29V @60% Duty Cycle

- Weight: 32kg

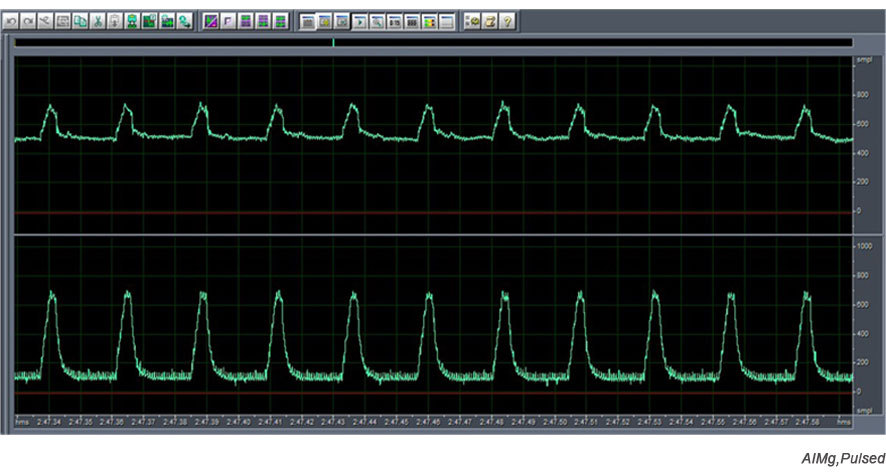

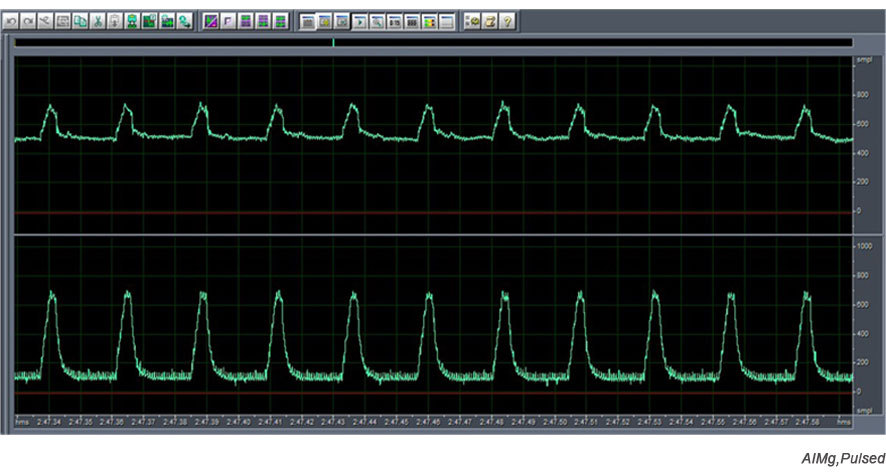

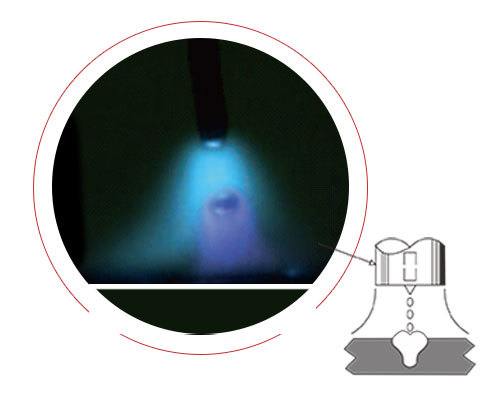

The advantage of Wave-form Control System

The latest technology of Waveform Control System with pulsed MIG control mode, can perfectly control the output of

welding power and get the precision Arc performance. The wire melting droplet transfer cycle is very clear, the welding

beam is very clean and very few spatters during welding.

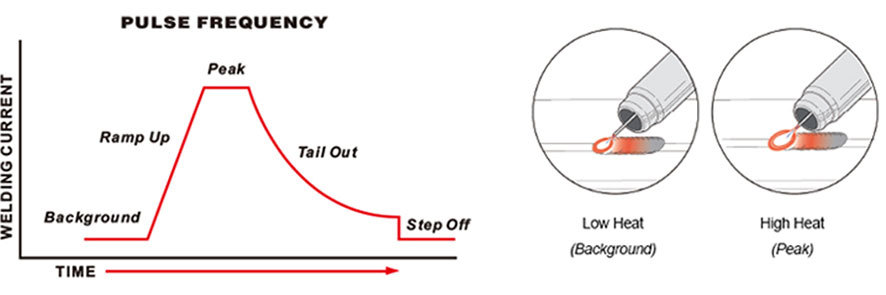

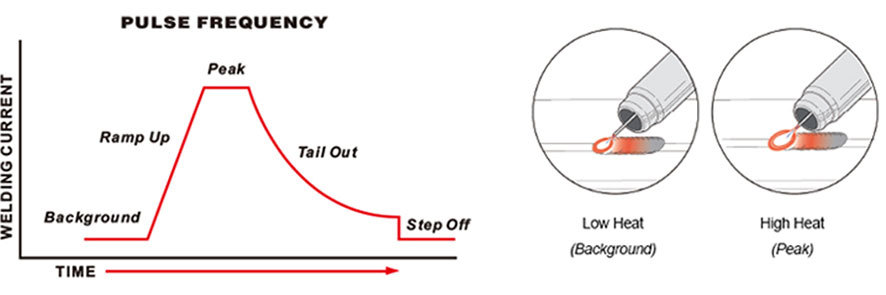

Pulse MIG

Pulsed MIG varies weld current between peak (high heat) and background (lowheat) current to provide better control of

heat input, which minimizes warping and burnthrough on thin materials. Pulsed MIG also enables flat,horizontal, vertical

up, or overhead welding without a slag system.Optimized GMAW-P waveforms are readily available to use on aluminum,

carbon steel,high strength low alloy steel, stainless steel,and nickel alloys. See NX-2.70

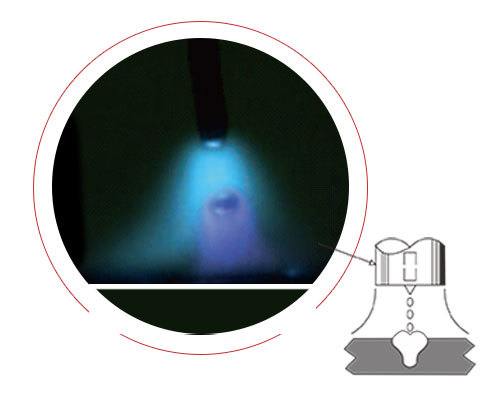

PULSED MIG

Pulse MIG precisely controls heat input through the

1-drop-per-pulsetransfer and offers a stable arc in the

wide transfer area between short and spray arc.

Spray arc transfer “sprays” a stream of tiny molten

droplets across the arc, from the electrode wire to the

base metal.It produces a characteristic humming

or buzzing sound. Advantages of pulse mig:

• High deposition

• Good fusion and penetration

• Good bead appearance

• Capability of using larger diameter wires

• Presence of very little spatter |  |

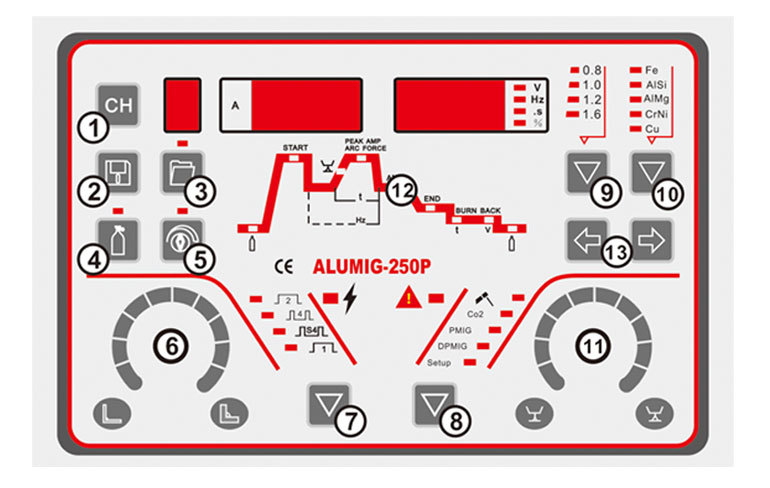

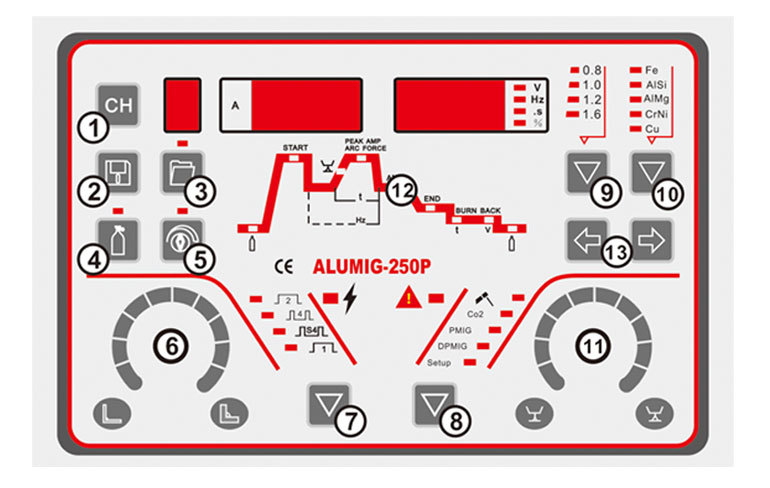

General View of Control Panel

1.SELECT the Memory channel

2.OPEN the parameter of selected memory channel

3.STORE the setting to Memory channel

4. Push to Check Gas

5.STORE Push to use Synergic Setting

6.Welding parameter setting,rotary dial

Adjudtment of the welding current or feeding speed.

7.Torch Holding Mode

Push to select the torch handing type:

1)2T | 2)4T

3)S4:for aluminiu welding form cold to hot situation.

8.Welding Process Push to select:

Welding prcess:MMA,MIG/MAG/CO2,Pulse MIG,

Double Pulse MIG.

9.Dia. of Welding Wire

10.Wire Type

11.button,throttling effect(arc dynamics)

12.Function Sequence

13.Welding Settings |

Synergic MIG

| Synergic pulsed welding mode offers the simplicity of

single-knob control.The machine will select the correct pulse

power based on the wire feed speed (WFS) set by the operator. |

S4T Mode

| Begin and end welds with ease and confidence.Hot start

eliminates incomplete fusion at the beginning of a weld,

a common issue with aluminum welding.Crater gradually

decreases weld current at the end of a weld to eliminate

crater defects.Adjustable pre- and post-flow rates ensure

that the puddle always has adequate gas coverage. |

/SPECIFICATIONS

Technical specifications

| Item No | ALUMIG-250P | ALUMIG-300P |

|---|

| Rated Input Voltage | 1PH ~ 230V ±15% | 3PH ~ 400V ±15% |

| Max. Load Power Capacity | 10.35KVA | 12.04KVA |

| Rated Duty Cycle(40℃) 60% | MIG: 250A/26.5V | MIG: Separated Wire-feeder: 300A/29V |

| | | Internal Wire-feeder: 250A/26.5V |

| | MMA: 250A/28V | MMA: 250A/28V |

| 100% | MIG: 200A/24V | MIG: 200A/24V |

| | MMA: 200A/28V | MMA: 200A/28V |

| Welding Current/Voltage Range | MIG: 30A/15.5V~250A/26.5V | MIG: 30A/15.5V~300A/29V |

| | MMA:30A/20.4V~250A/28V | MMA:30A/21.2V~250A/28V |

| Open Circuit Voltage | 55V | 55V |

| Power Factor | 0.8 | 0.85 |

| Efficiency | 80% | 85% |

| Pre-Gas Time | 0-15S | 0-15S |

| Flow-Gas Time | 0-15S | 0-15S |

| Wire-feed Mechanism | 4 Rollers | 4 Rollers |

| Wire-feed Speed Range | 0~25 m/min | 0~25 m/min |

| Wire Spool Capacity | 300mm (5kg) | 300mm (5kg) |

| Filler Wires Ø (mm) Fe, Ss: | 0.6~1.2 mm | 0.6~1.6 mm |

| FLUX CORED: | 0.9~1.2 mm | 0.9~1.6 mm |

| Al: | 0.8~1.2 mm | 1.0~1.6 mm |

| Dimension | 770X250X650mm | 770X250X650mm |

| Weight | 32KG | 33KG |

/ACCESSORIES

For Standard accessories

Electrode holder with cable 2M

For Optional accessories

CO2 gas regular with heater

/VIDEOS

/DOCUMENTS