Search This Supplers Products:welding machineAc/Dc Tig WelderPulse Mig WelderPlasma CutterMig Welding MachineTig Welding Machine

plasma cutting machine CLEAN GOUGE 130HD

- group name

- Plasma Gouging

- Min Order

- 1 piece

- brand name

- TOPWELL

- model

- CLEAN GOUGE 130HD

- Nearest port for product export

- Shanghai/Ningbo Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T

- Export mode

- Have the independent export and import right

- update time

- Fri, 27 Feb 2026 02:13:58 GMT

Paramtents

Input Voltage 3PH ~ 400V ±15%

Duty Cycle Rating 40℃(105℉) 130A@100%

Max. Load Power Capacity 28.4KVA

Input Voltages 380V/440V, 3PH, 50/60Hz

Packging & Delivery

- 75cm x36cm x71cm

-

Min Order1 piece

Briefing

Delivering maximum power and performance for clean gouge, Professional Mechanized Plasma Gouging System

Detailed

DETAILS

CLEAN GOUGE 130HD

For the professional plasma gouging, we have 2 machines:

1.Clean Gouging 130HD: universal steel gouging, air+air dual system

2.INOX Gouging 160MAX: special designed for S.S. (Ni/Ti based), by H35+N2 gas (high-definition).

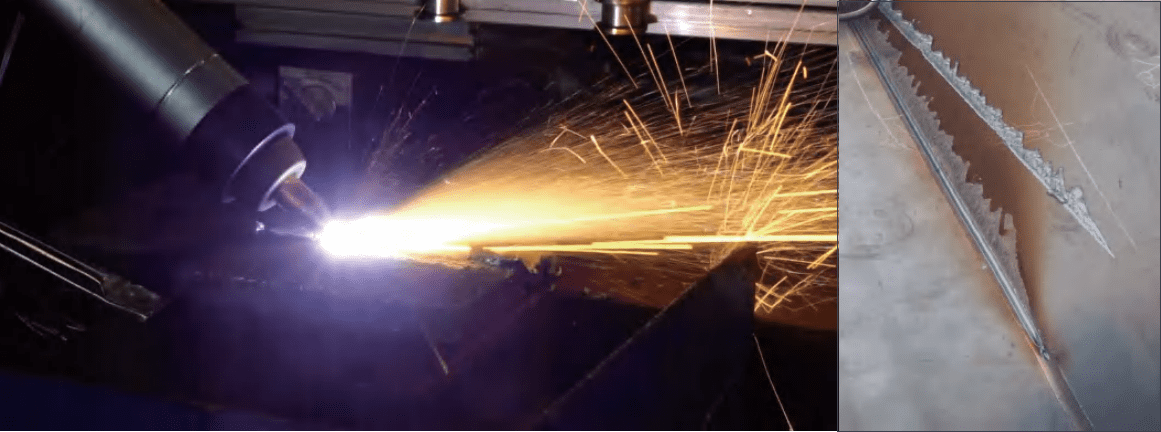

Here is our Clean Gouging 130HD video

ideal for eliminating welding defects, cracks, cavities and inclusions and for preparing for backwelding.

CUTTING CAPACITY

|

Capacity

|

Thickness

|

Cut Speed

|

|

Cutting

|

||

|

Dross Free(CNC)

|

18mm

|

900mm/min

|

Pierce* | 25mm | |

Recommend | 38mm | 500/min |

|

Severance (Hand Cutting)

|

60mm

|

125mm/min

|

*Pierce rating for handheld using or with CNC torch height control

Advantage compare to Arc gouging

1.Higher Removal Rate Of Material Than Gouging With Carbon Electrode

2.Easy Process Handling

3.No Finish Grinding Required

4.Good Tracking Of Gouging Process

5.No Carbonisation Of The Material

6.Low Heat Input

7.Reduction Of Noise & Smoke Levels

APPLICATION

Plasma gouging is ideal for eliminating welding defects, cracks, cavities and inclusions and for

preparing for backwelding.

1.Preparation Of Reverse Side Welding (Sealing Runs)

2.Removing Of Defects On The Surface Of Materials

3.Adjustment Of Different Material Cross-sections

4.Groove Face Preparation

5.Cleaning & Polishing Of Castings

6.Peeling Of Material On Surfaced Workpieces

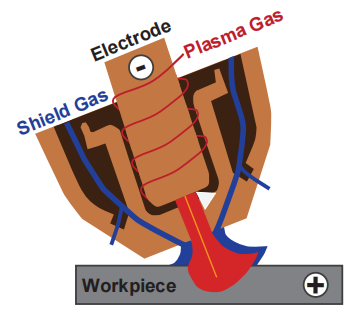

UNIQUE TECHNOLOGY

Side Blowing

Side Blowing Dual Air Plasma Gouging System

Unique side blowing technology provide good track of

gouge process,better control of gouging depth and width,

which improve gouging efficiency

Dual Air Plasma Gouging System

Separate plasma and shielding gases to optimize the

performance.

TORCH TP200G

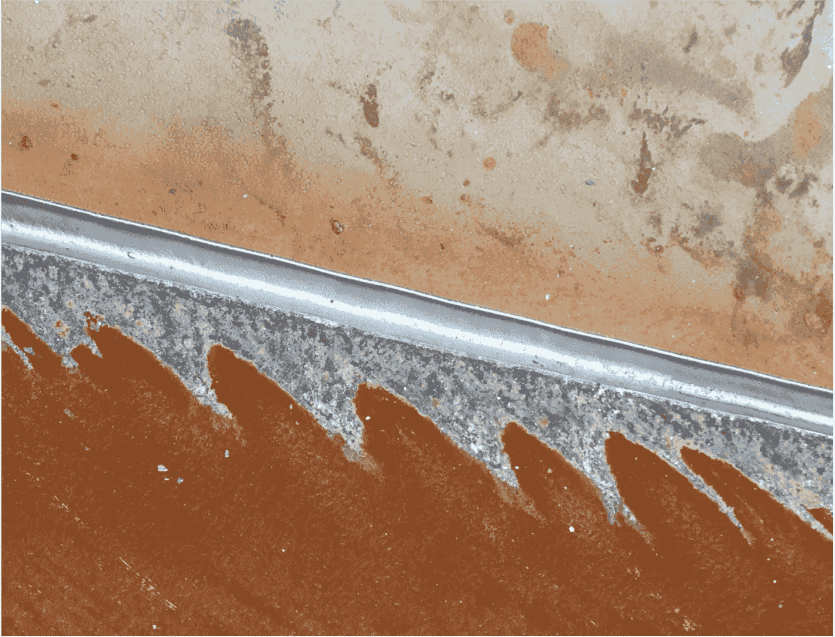

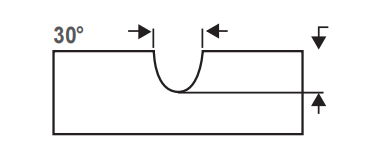

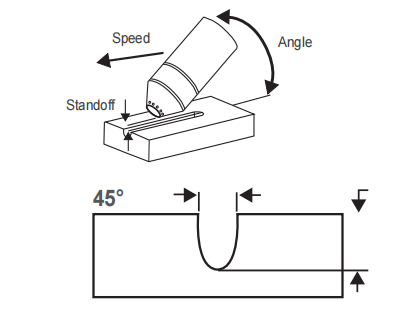

GOUGE PROFILE

You can vary the gouge profile by varying the:

Speed Of The Torch Over The Workpiece

Torch-to-work Standoff Distance

Angle Of The Torch To The Workpiece

Current Output Of The Power Supply

Profiles by 30° and 45° a torch angles are illustrated as above.

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

CLEAN GOUGE 130HD

|

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

680*310*650mm

|

|

Net Weight

|

49KG

|

Basic Specification

|

Input Voltage

|

380V/400V, 3PH, 50/60Hz

|

|

Input Power

|

28.4KVA

|

|

Rated Output Voltage

|

175VDC

|

|

Max Output Current

|

130A

|

Open Circuit Voltage (OCV) | 380VDC |

Operating Temperature | -10℃~40℃ |

Duty Cycle Rating 40℃(105℉) | 100%@130A |

Torch | TP200G |

YOU MAY ALSO NEED

air Regulator

BK1101