Search This Supplers Products:welding machineAc/Dc Tig WelderPulse Mig WelderPlasma CutterMig Welding MachineTig Welding Machine

PROMIG-250SYN DPulse Synergy Pulse and Double Pulse MIG Welder

- group name

- All products

- Min Order

- 1 piece

- brand name

- TOPWELL

- Nearest port for product export

- Shanghai/Ningbo Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T

- Export mode

- Have the independent export and import right

- update time

- Tue, 27 Jan 2026 22:26:10 GMT

Paramtents

Input Voltage 1PH ~ 230V ±15%

Rated Output(40℃) 60% 250A/26.5V

Features Pulse & Double Pulse MIG

Wire Feeder 4-Rollers

Packging & Delivery

- 75cm x36cm x71cm

-

Min Order1 piece

Briefing

The PROMIG-250SYN DPulse is heavy duty design and suitable for workshop or light industrials.

Detailed

DETAILS

Synergy, Pulse, Double Pulse MIG

PROMIG-250SYN DPulse

Multi-Process Capable - Welds Flux-cored, Stick, Pulse MIG, advanced MIG for M.S/S.S.

Pulse MIG Process - Welds 4XXX and 5XXX series aluminum for superior quality welding.

Synergic Control - Set weld procedures with one control.

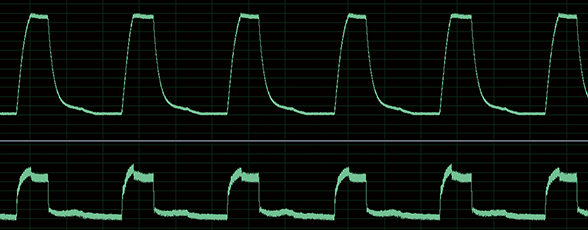

Built-in featured waveform - Provides a smooth, stable arc and superior, repeatable welds.

Dynamic Control - controls the welding arc cone width from a softer arc to a harder arc.

True Pulse MIG For Aluminum

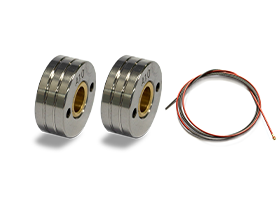

4-Roller wire-feeder

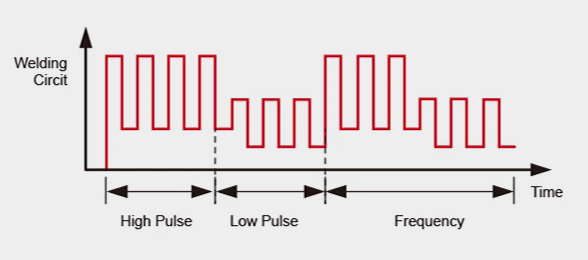

No need to swing, You can easily get a cosmetically pleasing weld seam, with significantly lower and more controller heat input into the workpiece. It results in much lower distortion and less rework, very suitable for welding the thin Aluminum sheets.

By Double Pulse process, the heat input of arc is alternating, effectively reducing the heat input of base metal. It reduces the occurrence of welding defects such as crack.

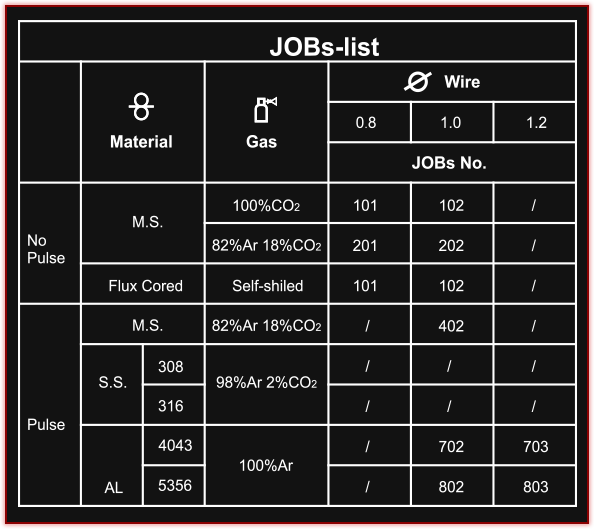

True Synergy With Jobs-list

| The Job-lists display is easily and intuitively controlled through its graphical user interface.We assembled the perfect welding curve in every Job-No. for highly efficient multi-process welding of carbon steels and stainless steel and aluminum alloys. Operation is easier than ever before. |

3 Steps To Start Perfect Welding

1. Regarding to the Job-List, set Job Number

2. Regarding to the base metal thickness,set welding current

| 3. Go for welding! |

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

ProMIG-250SYN DPulse

|

|

Machines Processes

|

Stick (SMAW) Flux-Cored (FCAW) MIG (GMAW) Pulsed MIG (GMAW-P) Double Pulsed MIG (GMAW-DP) |

|

Wire Feeder

|

4-Rollers

|

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

790x250x650mm

|

|

Net Weight

|

32kg

|

Basic Specification

|

Input Voltage

|

1PH ~ 230V ±15%/3PH ~ 400V ±15%

|

|

Input Power

|

11.72KVA

|

|

Output Range

|

MIG: 10A/14.5V ~250A/26.5V MMA: 20A/20.8V~250A/30V |

|

Rated Output(40℃) 100%

|

MIG: 250A/26.5V MMA: 250A/30V |

Polarity | DC |

YOU MAY ALSO NEED