Search This Supplers Products:welding machineAc/Dc Tig WelderPulse Mig WelderPlasma CutterMig Welding MachineTig Welding Machine

high definition steel cutting machine CNC Plasma cutter HD300

- group name

- All products

- Min Order

- 1 piece

- brand name

- TOPWELL

- model

- HD300

- Nearest port for product export

- Shanghai/Ningbo Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T

- Export mode

- Have the independent export and import right

- update time

- Thu, 12 Feb 2026 01:09:48 GMT

Paramtents

Rated Input Voltage 340-460V, 3-PH, 50-60Hz

Max Input current 340/460V, 228/169A

Rated Open-circuit Voltage 380V

Effiency 85%

Output current 30-300A

Rated output voltage 200V

Power supply type Inverter-IGBT

Warranty 1 year warranty

Dimensions 1560X700X1830MM

Weight 256KG

Packging & Delivery

- 156cm x70cm x183cm

-

Min Order1 piece

Briefing

HD300 is designed specially for CNC cutting, with rated 100% duty cycle,very heavy duty and powerful

Detailed

DETAILS

HD300W

Heavy Duty, High Performance, Long Consumable Life Plasma Cutting System

Cutting Capacity

|

Mild Steel Cut Capacity

|

Thickness

|

|

Dross free*

|

32mm |

Production pierce | 38mm |

Maximum cutting capacity | 80mm |

High Performance Cutting

• HD300W plasma cutting system cuts fine-feature parts with superior quality and consistency, eliminating the cost of secondary operations.

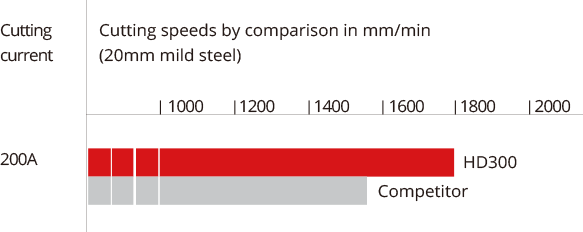

• The focused plasma arc for more powerful precision cutting up to 38mm on Mild Steel and 32mm on Stainless steel and Aluminum.

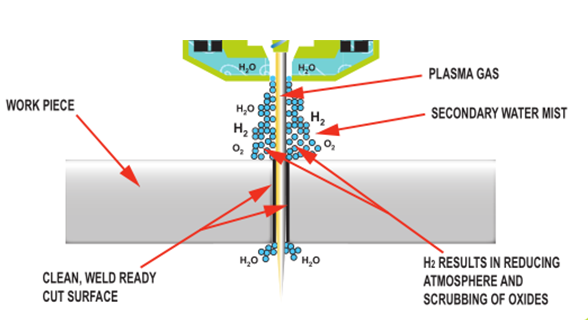

• With water spray cutting process, the stainless steel and aluminum cutting will be less warping and produce a small heat-affected zone.

Water Mist Secondary (WMS) Technology

Long Consumable Life & Fast Cutting Speed

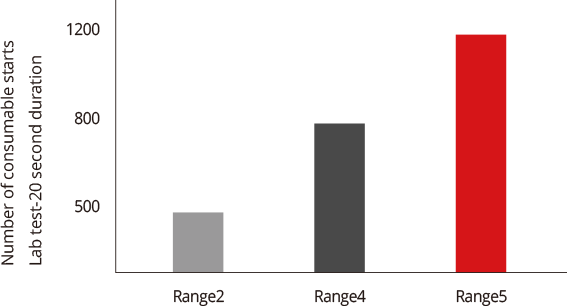

Long Consumable Life

• 12mm mild steel;

• 200A Air/Air;

• 20s duration;

• The number of consumable starts can reach more than 500 times (ISO9013 Range 2).

Fast Cutting Speed

The cutting speed of dross free can reach 1200mm/min for 20mm mild steel.

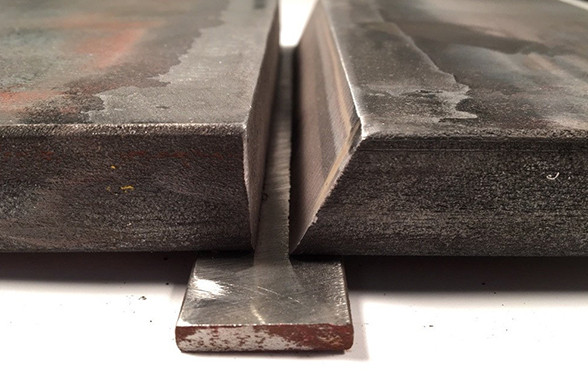

Bevel Cutting Technology

Bevel Cutting Technology is a performance application for mild steel. Factory tested and easily implemented, it takes the guesswork out of the plasma bevel-cutting process. With Bevel Cutting Technology, setups for new jobs are quick and results are accurate and consistent.

• 1 iteration

• Using True Bevel

• Acceptable part and ready to start production

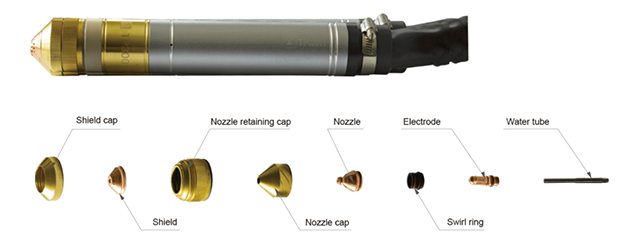

Refined Torch System

• Double air system torch;

• Nozzle cooling for increased electrode life and reduced operating costs;

• Work with TOPWELL high voltage power source to shift the cutting limitation.

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

HD300W

|

|

Cut angle(ISO 9013 range*)

|

2

|

|

Weldability

|

Ready to weld

|

|

Plasma gas

|

Air

|

Shield gas | Air; Water Spray |

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

1300*800*580mm

|

|

Net Weight

|

235KG

|

Basic Specification

|

Input Voltage

|

380V/400V, 3PH, 50/60Hz

|

|

Input Power

|

75KVA

|

|

Rated output voltage

|

50~200VDC

|

|

Rated Output(40℃) 100%

|

300A

|

Open circuit voltage (OCV) | 430VDC |

* ISO 9013 is a standard that defines cut quality of thermally cut parts. The lower the range (range 1 is the lowest), the smaller the angle on the cut face. Cut angle in range 4 is better than in range 5.

YOU MAY ALSO NEED

TP300 Consumable Kit