Search This Supplers Products:welding machineAc/Dc Tig WelderPulse Mig WelderPlasma CutterMig Welding MachineTig Welding Machine

MIG welding machine with Pulse MIG ProMIG-250SYN Pulse

- group name

- All products

- Min Order

- 1 piece

- brand name

- TOPWELL

- model

- PROMIG-250SYN

- Nearest port for product export

- Shanghai/Ningbo Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T

- Export mode

- Have the independent export and import right

- update time

- Wed, 11 Feb 2026 17:56:51 GMT

Paramtents

Rated Input Voltage 1PH~230V ±15%/3PH~400V ±15%

MAX.Load Power Capacity 11.72KVA

Rated Output 250A/26.5V

Open Circuit Voltage 70V-80V

Effiency 80%

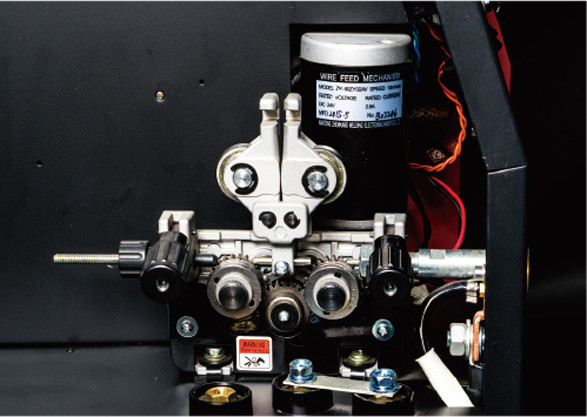

Wire-feed Mechanism 4Rollers

Wire Feed Speed Range 2-25m/min

Warranty 3 year warranty

Dimension 790x250x650mm

Weight 32KG

Packging & Delivery

- 85cm x33cm x67cm

-

Min Order1 piece

Briefing

PROMIG-250SYN is a 3 in 1 MIG TIG lift MMA welding machine , Synergic with JOBS-LIST, pulse mig welder

Detailed

DETAILS

Heavy Duty, Synergy, Pulse MIG

PROMIG-250SYN Pulse

Compact Heavy Duty Design - 250A @ 60% Duty cycle, suitable for workshop or light industrial

Multi-Process Capable - Welds Flux-cored, Stick, Lift-TIG, Pulse MIG, advanced MIG for M.S/S.S.

Pulse MIG Process - Welds 4XXX and 5XXX series aluminum for superior quality welding.

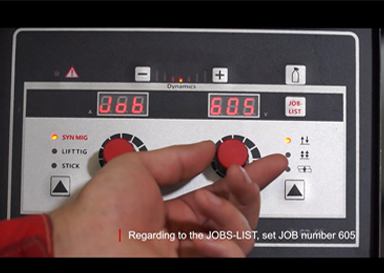

Synergic Control - Start welding with three simple steps.

Built-in featured waveform - Provides a smooth, stable arc and superior, repeatable welds.

Dynamic Control - controls the welding arc cone width from a softer arc to a harder arc.

True Pulse MIG For Aluminum

Low Spatters For Mild Steel

PROMIG-250SYN Pulse is not just an aluminum welding expert, it also has nice results on M.S/S.S welding. With the advanced welding curves from Mastert's Jobs-list (Short circuit transfer), there is low spatters while welding M.S and save your time for secondary work.

4-Rollers Wire-Feeder

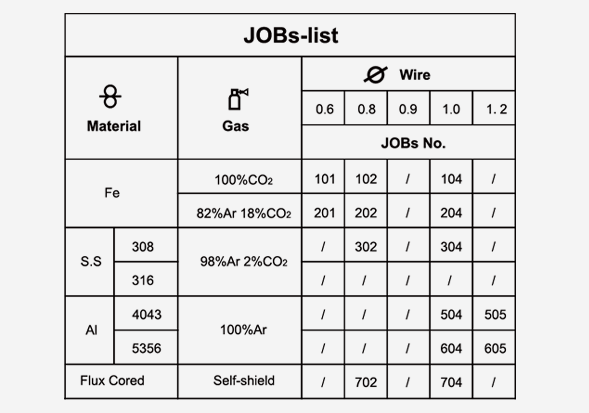

True Synergy With Jobs-list

The Job-lists display is easily and intuitively controlled through its graphical user interface.We assembled the perfect welding curve in every Job-No. for highly efficient multi-process welding of carbon steels and stainless steel and aluminum alloys. Operation is easier than ever before.

3 Steps To Start Perfect Welding

1. Regarding to the Job-List, set Job Number

2. Regarding to the base metal thickness,set welding current

| 3. Go for welding! |

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

ProMIG-250SYN Pulse

|

|

Machines Processes

|

Stick (SMAW) Flux-Cored (FCAW) MIG (GMAW) Pulsed MIG (GMAW-P) |

|

Wire Feeder

|

4-Rollers

|

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

790x250x650mm

|

|

Net Weight

|

32kg

|

Basic Specification

|

Input Voltage

|

1PH ~ 230V ±15%/3PH ~ 400V ±15%

|

|

Input Power

|

11.72KVA

|

|

Output Range

|

MIG: 10A/14.5V ~250A/26.5V TIG: 5A/10.2V~250A/20V MMA: 20A/20.8V~250A/30V |

|

Rated Output(40℃) 100%

|

MIG: 250A/26.5V TIG: 250A/20V MMA: 250A/30V |

Polarity | DC |

YOU MAY ALSO NEED