Search This Supplers Products:welding machineAc/Dc Tig WelderPulse Mig WelderPlasma CutterMig Welding MachineTig Welding Machine

TOPWELL PROMIG 250XP Double Pulse Welding Machine - Professional OEM Solutions

- group name

- All products

- Min Order

- 1 piece

- brand name

- TOPWELL

- model

- PROMIG 250XP

- Nearest port for product export

- Shanghai/Ningbo Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T

- Export mode

- Have the independent export and import right

- update time

- Mon, 10 Mar 2025 19:22:50 GMT

Paramtents

Input Voltage 1PH ~ 230V ±15%

Rated Output(40℃) 60% 250A/26.5V

Features Pulse & Double Pulse MIG

Wire Feeder 4-Rollers

Packging & Delivery

- 95cm x46cm x102cm

-

Min Order1 piece

Briefing

Experience excellence in welding with TOPWELL PROMIG 250XP. Double Pulse technology for superior results. Available for OEM/ODM

Detailed

DETAILS

Refined Pulse and Double Pulse MIG

PROMIG 250XP

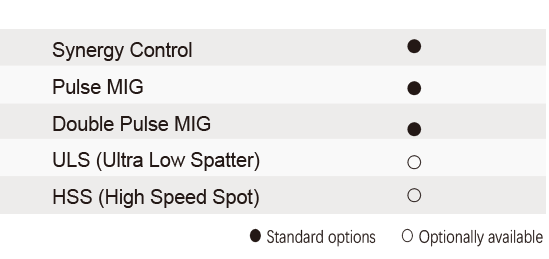

Synergy Control

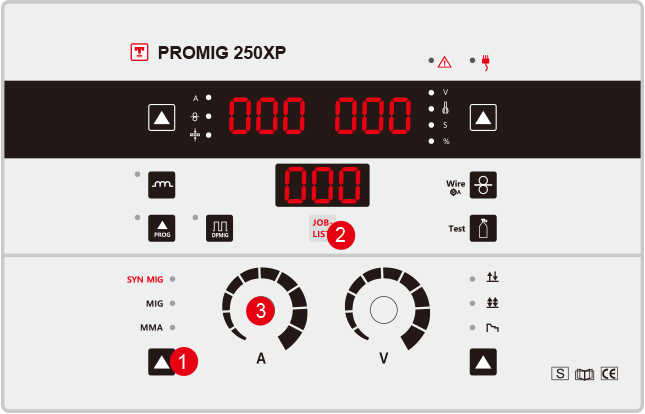

Set weld procedures with one control. Just easily takes 3 Steps to achieve weld perfection.

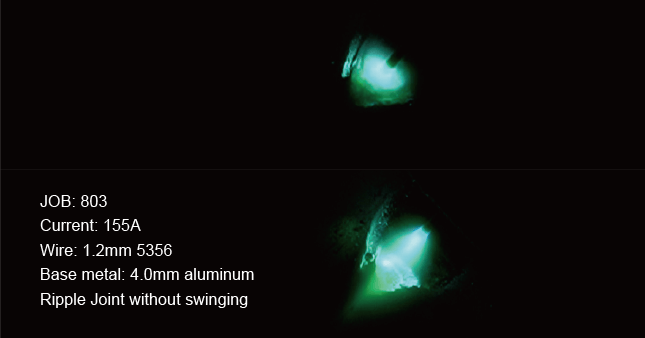

Superior aluminum performance

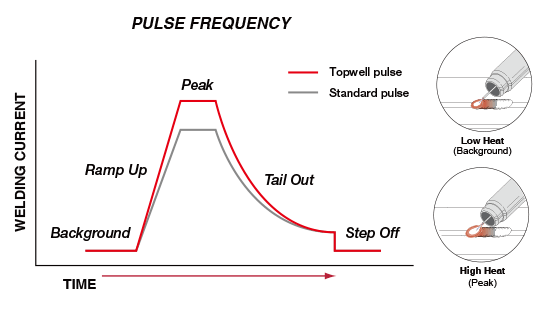

The upgraded pulse MIG has higher peak current and larger energy reserve. The perfect waveform achieves the heat control for aluminum welding, and virtually eliminates burn-through and warping issues on thinner materials. With double pulse, no need to swing, get better weld quality and appearance.

Improved Operation Process & Controls

Initial Arc control, Burn Back control, Arc Length control, Dynamic control, these make an easier operation and handling for welding.

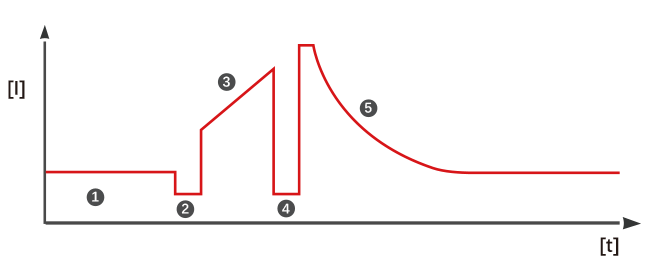

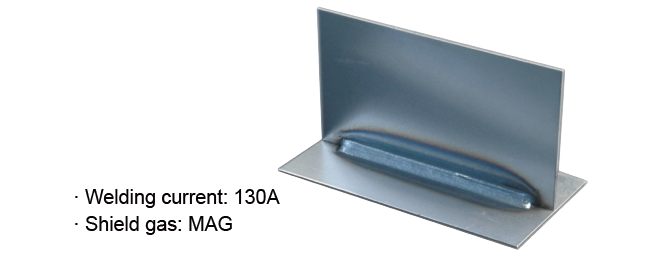

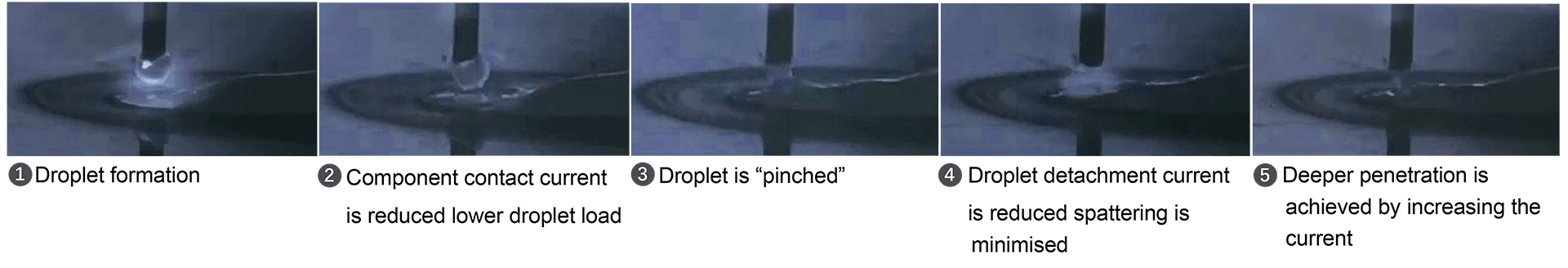

Ultra Low Spatter (ULS)

It is a modified short-arc transfer arc, it controls the volatility during the change of state between short and arc to control the amount and size of the spatter generated. Up to 75% less spatter, up to 25% saving on gas costs.

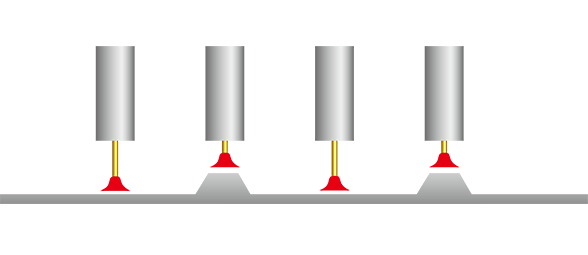

High Speed Spot (HSS)

Offers a faster travel speed and better welding performance, especially for thin (less than 2mm) pipes or frame/structure welding jobs, like the furnitures etc.

Simple Operation

3 Steps to achieve weld perfection

1. Select operation mode

2. Select Job-list No.

3. Adjust welding current

(always the perfect setting by the synergic function using the material thickness)

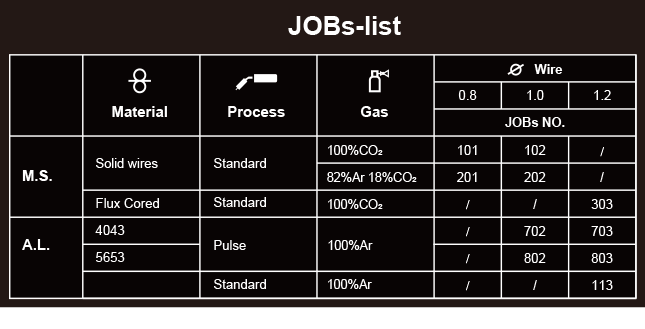

Synergy Control With Job-list

The Job-lists display is easily and intuitively controlled through its graphical user interface.We assembled the perfect welding curve in every Job-No. for highly efficient multi-process welding of carbon steels and stainless steel and aluminum alloys. Operation is easier than ever before.

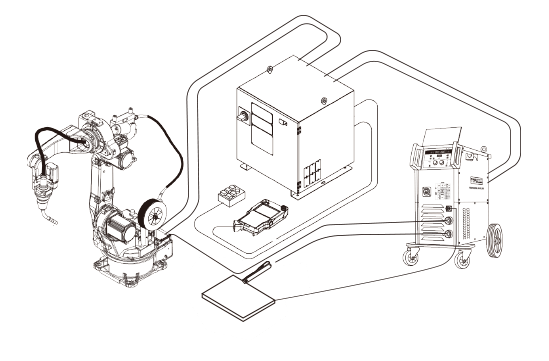

Separated wire feeder & remote control, robotic ready (as optional)

Robotic with advanced MIG process package, achieve ultra-high efficient welding with perfect welding performance. Optional package for robot interface by Analog connectors or Digital ports including EtherNetlP, DeviceNet, CAN, CANOPEN, RJ485 etc.

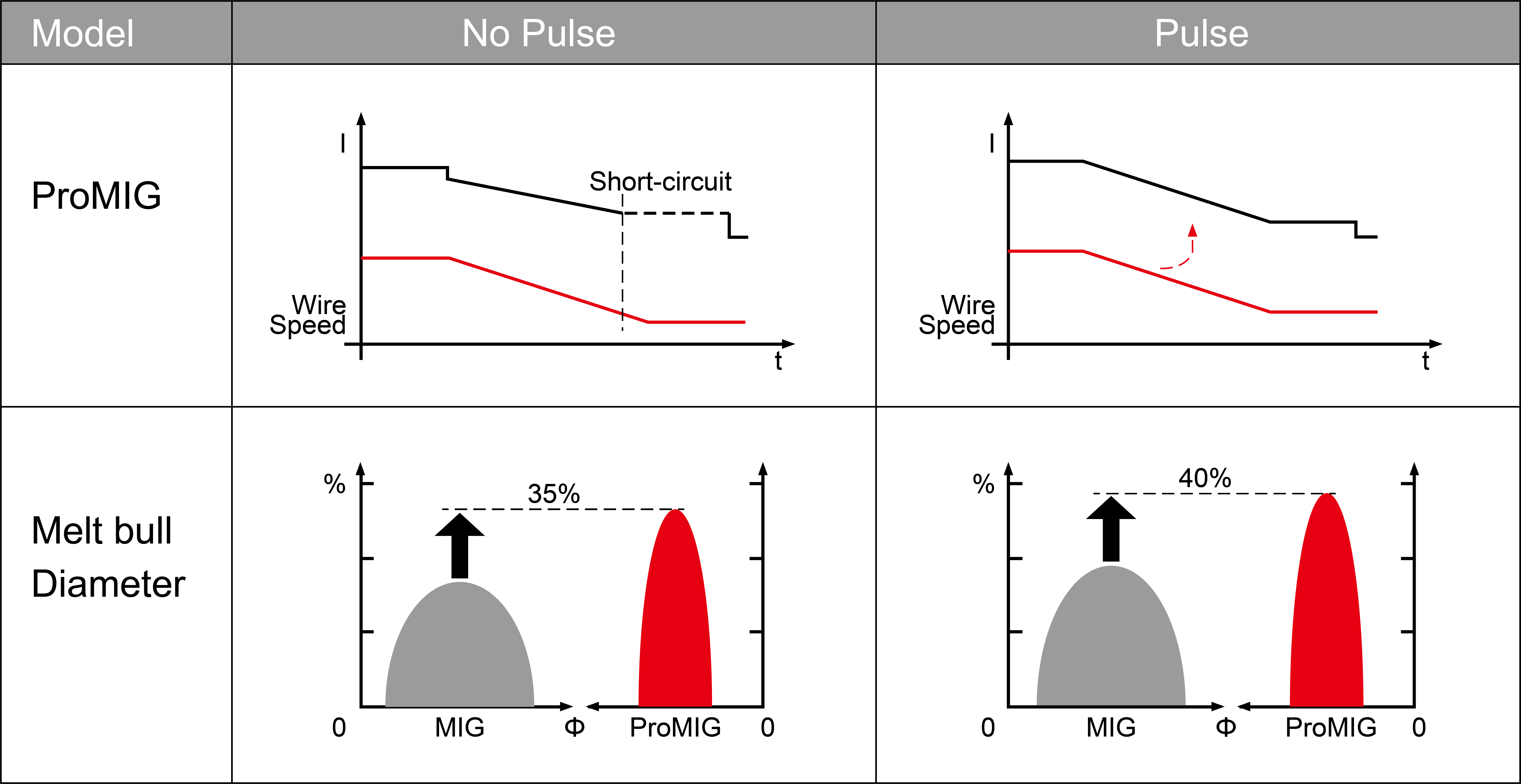

Pulse MIG with larger current difference

The PROMIG 250XP is an upgraded module and machine that is compatible with more advanced pulse processes. The PROMIG 250XP improves on the standard pulsing process to provide a higher peak current and a larger current difference that is more suitable for aluminum alloy welding. As wire speed increases/decreases, the pulse or MIG parameters also increase/ decrease to match the right amount of power needed to achieve a more perfect welding curve.

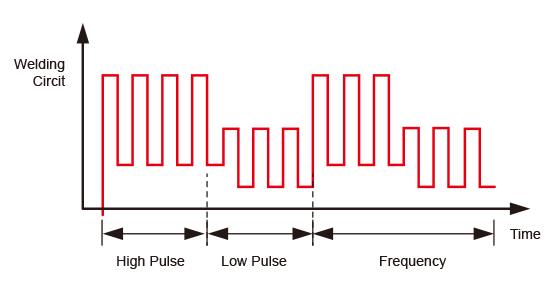

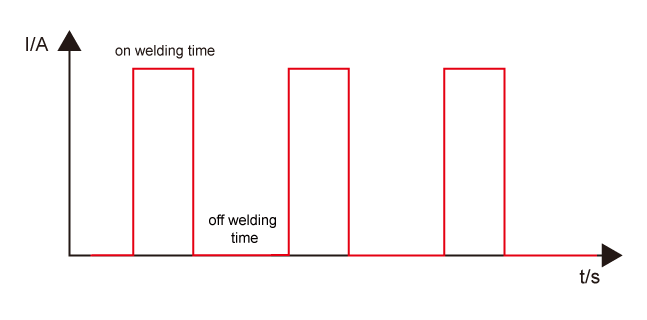

Double Pulse MIG

The double pulse is a combination of the Pulse MIG process and the variation of the high and low currents, with the low pulse section providing cooling time to the melt pool while simulating the oscillation so that the melt pool oscillates. So no need to swing, You can easily get a cosmetically pleasing weld seam, with significantly lower and more controller heat input into the workpiece. It results in much lower distortion and less rework for Aluminum sheets.

By Double Pulse process, the heat input of arc is alternating, effectively reducing the heat input of base metal. It reduces the occurrence of welding defects such as crack. Welding quality is comparable to TIG process.

ULS - Ultra Low Spatters

The ULS process is a modified short-arc transfer arc with perfect waveform setting that greatly reduces spatter generation. In the pinch phrase, there is a special current interruption, the energy is extracted under the program setting, avoiding the explosion caused by the large current, and the surface tension of the molten pool warms the generated droplets. Even in CO2 and MAG welding, it can minimize the spatters, which means less rework, fewer rejects, less cleaning required and savings on wearing parts.

HSS - High Speed Spot Technology

HSS is the high speed spot welding, which is perfectly combining the welding process, arc physics, high dynamic power response and powerful motor control technology, short in arc ignition time and arc ending time, a welding spool can be formed swiftly. A spot welding cycle is quickly completed, cycle over and over, by adjusting the time gap with the robot to get the fish scale you wish, weld seam is clear and beautiful.

Improved Operation Process & Controls

Initial Arc control

We control the arc energy by welding waveform, so the success rate of arc ignition can be improved and quickly establish a molten pool.

Burn Back control

Adjustable time delay between turning off the arc and the wire feed to prevent wire sticking to the puddle.

Arc Length control

With the arc length control, no matter the changing distance between the torch and the workpiece, or the welding voltage, the arc length is kept constant, and the seam quality and appearance remain unchanged.

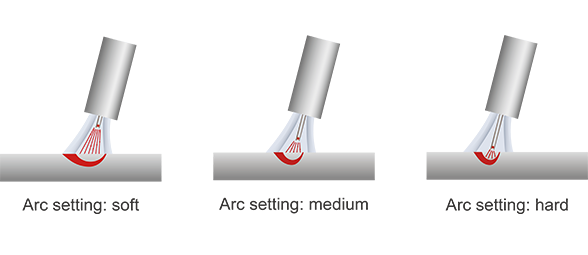

Dynamic control

The arc can easily be adjusted depending on the workpiece and positions as well as to the individual preferences of the welder through Dynamic Control. Changing the arc to soft or hard or anywhere in between, increases the reliability for a good root formation and side fusion even with a non-ideal position of the torch.

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

ProMIG-250XP

|

|

Machines Processes

|

Stick (SMAW) Flux-Cored (FCAW) MIG (GMAW) Pulsed MIG (GMAW-P) Double Pulsed MIG (GMAW-DP) |

|

Wire Feeder

|

4-Rollers

|

Product Weights & Dimensions

|

Dimensions(L*W*H):Machine

|

950x460x1000mm

|

Net Weight : Machine | 52KG |

Basic Specification

|

Mains voltage(V)

|

1PH 230V/3PH 400V/3PH 230/400V

|

|

Max.Load Power Capacity

|

14.88KVA

|

|

Rated Duty cycle at 40℃(105℉): 60%

|

360A/32V |

|

Rated Duty cycle at 40℃(105℉): 100%

|

250A/26.5V |

Open Circuit Voltage | 70V~80V |

Power Factor | 0.87 |

Efficiency | 89% |

Wire feed unit | 4 rollers |

Wire feed speed rang | 0~25m/min |

Wire Spool Capacity | 300mm(15kg) |

Wires φ (mm): Fe | 0.8~1.2mm |

Wires φ (mm): Alu | 0.8~1.2mm |

Wires φ (mm): Flux-cored | 0.8~1.2mm |

YOU MAY ALSO NEED