Search This Supplers Products:welding machineAc/Dc Tig WelderPulse Mig WelderPlasma CutterMig Welding MachineTig Welding Machine

Synergic double pulse mig mag welding machine promig-250syn dpulse

- group name

- All products

- Min Order

- 1 piece

- brand name

- TOPWELL

- model

- PROMIG-250SYN DPulse

- Nearest port for product export

- Shanghai/Ningbo Port

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T

- Export mode

- Have the independent export and import right

- update time

- Tue, 27 Jan 2026 13:51:59 GMT

Paramtents

Input Voltage 1PH ~ 230V ±15%

Rated Output(40℃) 60% 250A/26.5V

Features Pulse & Double Pulse MIG

Wire Feeder 4-Rollers

Packging & Delivery

- 75cm x36cm x71cm

-

Min Order1 piece

Briefing

Synergy, Pulse, Double Pulse MIG

Detailed

DETAILS

Synergy, Pulse, Double Pulse MIG

PROMIG-250SYN DPulse

Compact & Heavy Duty - 250A @ 60% Duty cycle, suitable for workshop or light industrial applications.

Synergic Control - Set weld procedures with one control. Just easily takes 3 Steps to achieve weld perfection.

Pulse MIG Process - Welds 4XXX and 5XXX series Aluminum and Mild Steel for superior quality welding.

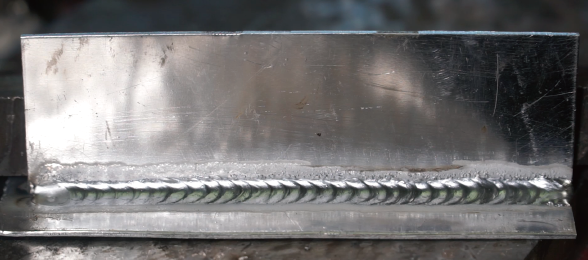

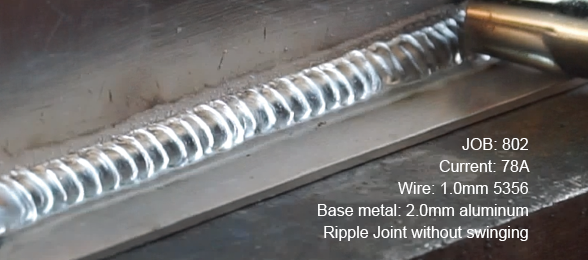

Double Pulse MIG Process - Delivers a staked dime appearance when welding mild steel and aluminum without swinging.

Advanced Performance For Mild Steel - Delivers less spatters, less rework than before.

Improved Operation Process & Controls - Initial Arc control, Burn Back control, Arc Length control, Dynamic control, these make an easier operation and handling for welding.

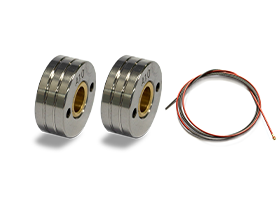

Professional 4-Rollers Wire Feeder - Four-rollers drive systems deliver theelectrode to the welding torch. It provides a stable wire speed and is popular for industrial applications.

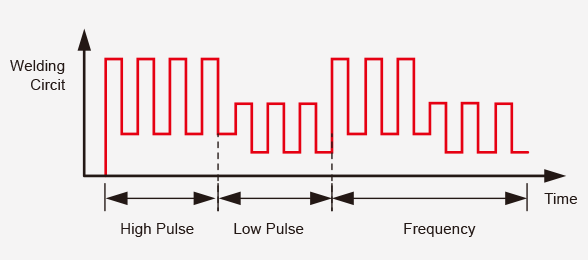

Pulse MIG

It minimizes warping and burnthrough on thin materials, not only for Aluminum, but also for Mild Steel. Moreover, it delivers ultra low spatters which is outstanding for Mild Steel welding.

Less Spatters For Mild Steel

ProMIG-250SYN DPulse is not just an aluminum welding expert, it also has nice results on M.S welding. With the advanced welding curves from Master's JOBS-LIST(short-circuit transfer), there is ultra-low spatters while welding M.S and save your time for secondary work.

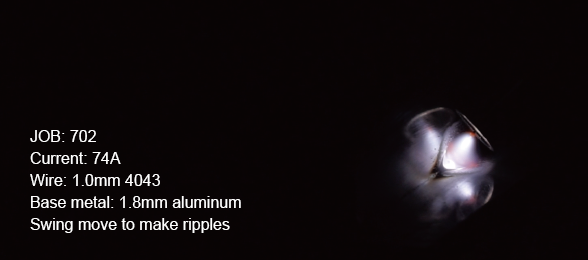

Double Pulse MIG

No need to swing, You can easily get a cosmetically pleasing weld seam, with significantly lower and more controller heat input into the workpiece. It results in much lower distortion and less rework for Mild steel and Aluminum sheets.

By Double Pulse process, the heat input of arc is alternating, effectively reducing the heat input of base metal. It reduces the occurrence of welding defects such as crack. Welding quality is comparable to TIG process.

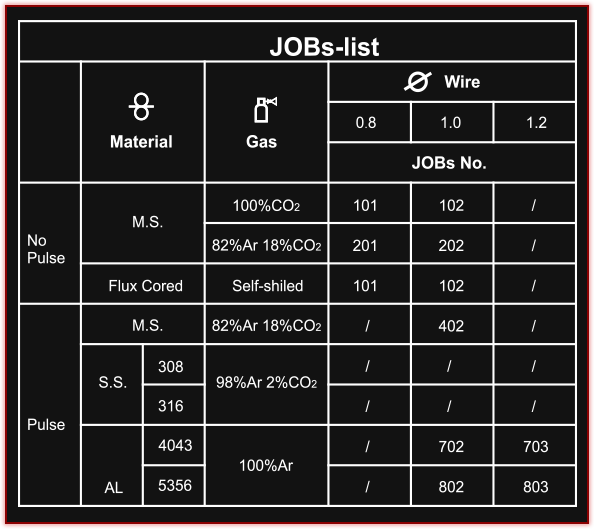

True Synergy With Jobs-list

The Job-lists display is easily and intuitively controlled through its graphical user interface.We assembled the perfect welding curve in every Job-No. for highly efficient multi-process welding of carbon steels and aluminum alloys. Operation is easier than ever before.

3 Steps To Start Perfect Welding

1. Regarding to the Job-List, set Job Number

2. Regarding to the base metal thickness,set welding current

| 3. Go for welding! |

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

ProMIG-250SYN DPulse

|

|

Machines Processes

|

Stick (SMAW) Flux-Cored (FCAW) MIG (GMAW) Pulsed MIG (GMAW-P) Double Pulsed MIG (GMAW-DP) |

|

Wire Feeder

|

4-Rollers

|

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

790x250x650mm

|

|

Net Weight

|

32kg

|

Basic Specification

|

Input Voltage

|

1PH ~ 230V ±15%/3PH ~ 400V ±15%

|

|

Input Power

|

11.72KVA

|

|

Output Range

|

MIG: 10A/14.5V ~250A/26.5V MMA: 20A/20.8V~250A/30V |

|

Rated Output(40℃) 100%

|

MIG: 250A/26.5V MMA: 250A/30V |

Polarity | DC |

YOU MAY ALSO NEED